-

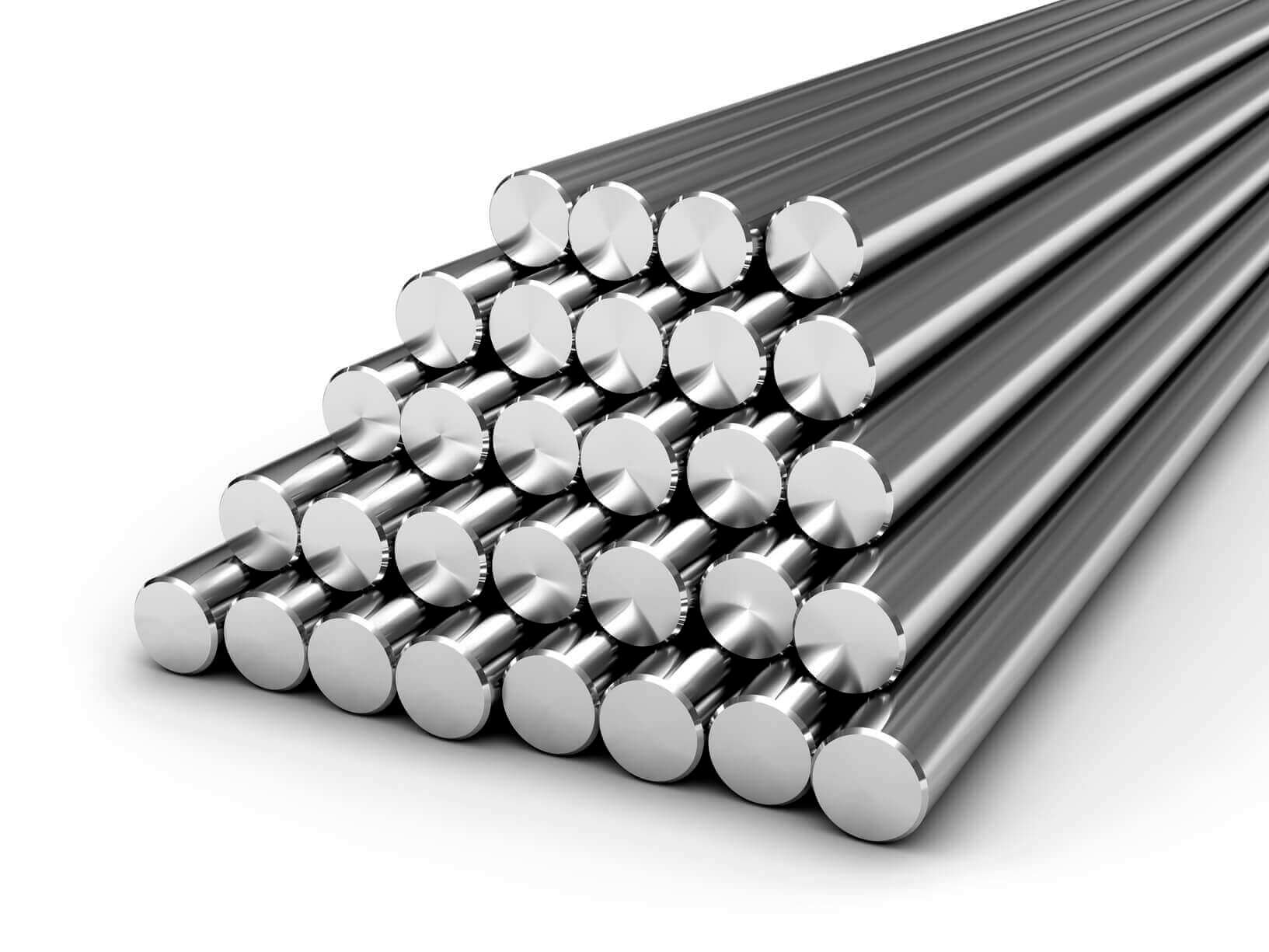

Raw Material

The raw material for the manufacturing of products is acquired from our solution partners abroad who are known for their quality and flawlessness. At Zeus Ortho Care, we take due care while procuring and storing the sensitive materials such as Titanium as per ISO 5832-3, Stainless Steel SS316 L , SS316 lvm, as per ISO 5832-1, ASTM A – 313 , ASTM F -138 , IS 6528 , polymers and aluminum in profiles, sheets, wires and tube forms. Instruments raw material are available in SS 420B, SS 440, Aluminum & Carbon Fibre.

-

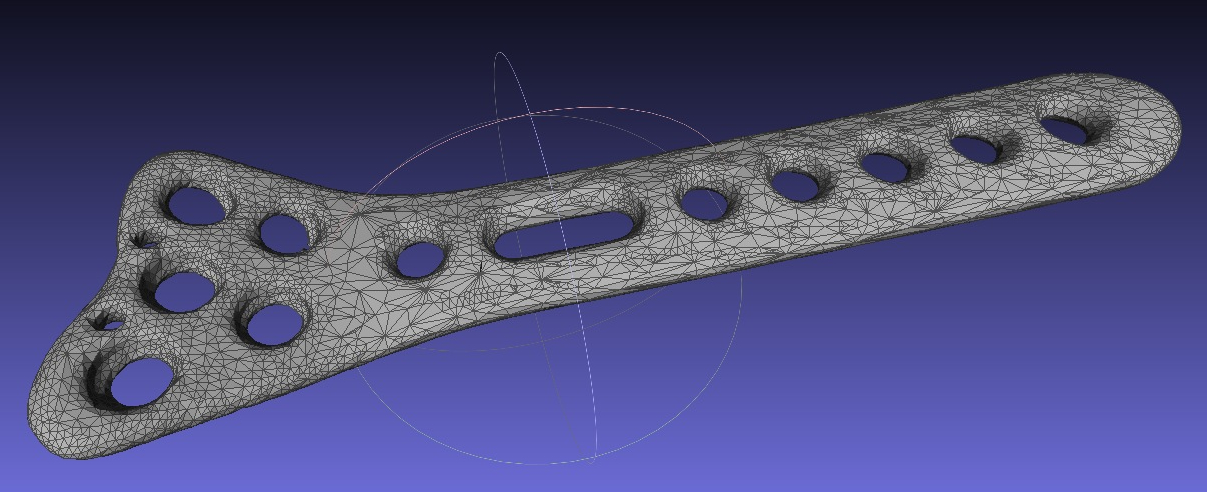

CAD/Design

The products are designed via technical drawing and 3D modeling by using software as per expectations and requirements of the engineers. Design process is continuously improved by ceaseless training studies. During design work process, thermal and fatigue analysis are realized by using finite elements method and present package software.

-

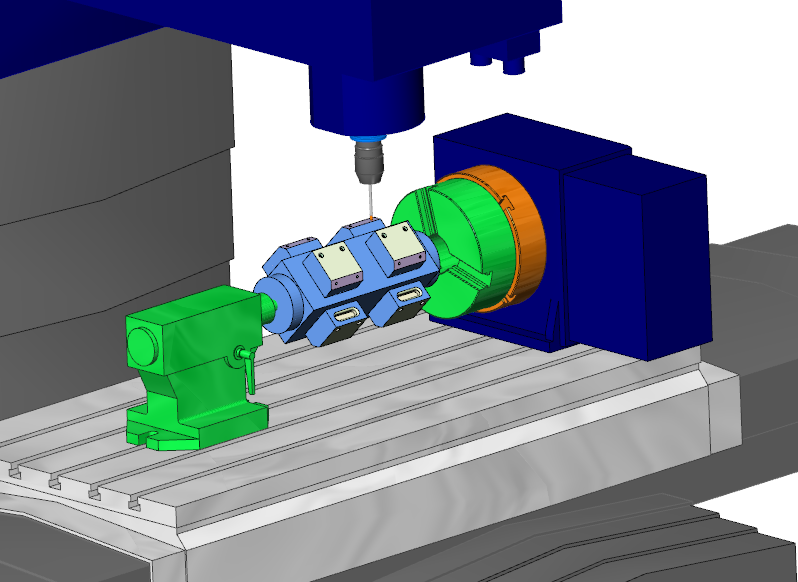

CAM Stage

We employ CAD/CAM programs in our corporation, in order to provide most effective solutions to our clients. Along with this professionally conducted process, and functionality, soundness and physical life of parts manufactured in our workshop with CNC and manual machines are assured by precision machining, surface treatments and assemblage operations. Zeus Ortho Care has the capacity to design and manufacture all machining/assemblage fixtures, measurement apparatus, gauges and process machines used during part production, in its own facilities.

-

Production

To maximize the benefits to our business partners, we provide them integrated solutions that help them increase their competitiveness and make their production stages more flexible. In order to ensure such high-level integration, we aimed at becoming an experienced institution with respect to processes and technology. Throughout this period, we are attentive to work with a continuous sense of quality in order to attain the right result. In order to maintain and improve this aspect, high quality mechanism for quality control and a department supervising machine usage parts always take place in production stages. The infrastructure formed with products, systems, and technologies from different sources carries us forward as a knowledge based company which both creates solutions and provide service. Our objective is to maintain our place globally and to strengthen our collaboration by presenting solutions, which meet industrial expectations, to our clients.

-

Machining

We attach great importance to take our production to higher levels with minimum error in machining. At Zeus Ortho Care we use CNC machines, vertical processing centers, manual lathes and milling machines in order to flawlessly satisfy the clients’ requirements. We invest a lot of efforts and time in research regarding mounted final product, mould, apparatus, sample and mass production parts.

-

Surface Treatments

The process before coating and coloring of materials, such as trimming, sanding, polishing, sand blasting, acid surface cleaning, pacifications, ultrasonic washing, rinsing and drying are realized fast and flawlessly in our own sections.

-

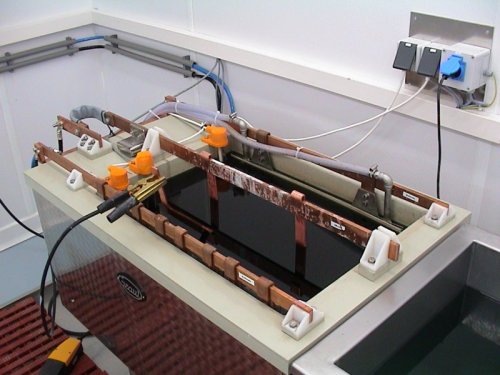

Color Anodizing

We have a very extensive color scale in our present section. Parameters such as environmental conditions, voltage values, waiting time, redactor sensitivity, solution rate, operator experience etc. determine the quality and sustainability of anodizing. Color coding gives surgeon to choose different sizes from far sight or can help in giving different identity to a product.

-

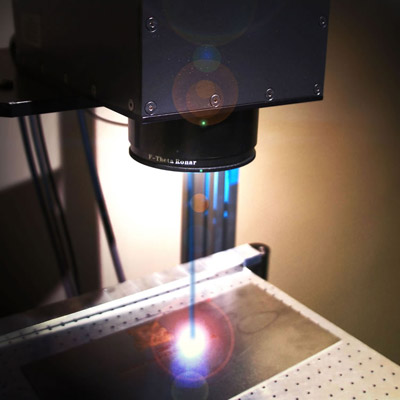

Laser Marking

The information such as company logo, barcode, size, lot number, expire date regarding products, reference codes, brand and other product details that do not evoke any suspicion regarding their quality, are inscribed on the product by laser marking device. Thus the laser marked Texts, logos and emblems can never be removed from the marked metal and thus cannot be subject to any malpractices thus indicating that the product is of first class quality.

-

Clean Room

Designed pursuant to norms ISO 14644-1 and under category Class 10000, offers extensive possibilities for customer requests and expectations. We continue to develop our infrastructure as per the technological up gradation required to provide better and improved solutions to the clients.

-

Packaging

The packaging operations are carried out in our facilities as non-sterile. During these stages, a fast and flawless packaging process is conducted in Clean Room, as well as in other units. Labeling on sealed pouches containing finished product.